Inkjet Printer for Cylindrical Objects

Cup printer has been developed in the recent years for printing on all kinds of cups,and still being updated.before the cup printer is developed,generally,the printing factory or the printing people print the photo onto the cup by traditional printing,such as the silk screen printing,but it often take a long time to make the plate of printing,and can't meet the instant and fast demand.and with the inkjet printing development,people start to print on series of flat materials with the flatbed printer,flatbed was developed earlier than the cup printer.

You may wonder how can our printer can print direct to the cup.because what we can know is the print surface must contact the cup,then the inks on the printing surface can be transferred to the surface of the cup?this way is different from the contact-type printing,it is actually noncontact-type printing.the printing surface is no need to contact the object directly.the advance inkjet printing technology has been adopted in this case.with the inkjet technology,the printer can spay inks from the print head onto the cups directly and correctly.for sure,the printer can calculate itself to know when to spray the inks and how many inks are supposed to spray.since the print head does not contact the surface of the product,so even though the material is thick or thin,that's Ok.though it is special-shape.what we need to do is adjust the distance between the heads and the product surface.you can set it quickly and easily by measure the cup's diameter first,and then set the value in the software.and then let the heads carridge go to the print position.

With this cylinder printer,you can print on cups and bottles with seamless connection effect,differ from the traditional printing,there is little gap or a little overlap that we can see clearly.this cylinder can print the seamless connection effect,people can not figure out where is the printing connection place.maybe you still can see some kinds of scan printers,these print adopt the scanning way to print,when it printing,the carriage move left and right,meanwhile,the bottle rotates step by step,this way still can print on bottles,but it will take far longer time,and it can not ensure the seamless connection effect,another way is that the 360 degree step print,even the bottle rotates with high speed,and the print head spaying inks onto the bottle,but the algorithm is not feasible.the seamless connection must adopt the most upgraded technology,the spiral printing.and we are using the spiral printing.

Specification

|

Items |

Description |

|

Printer Model |

GC-360 |

|

Print Applications |

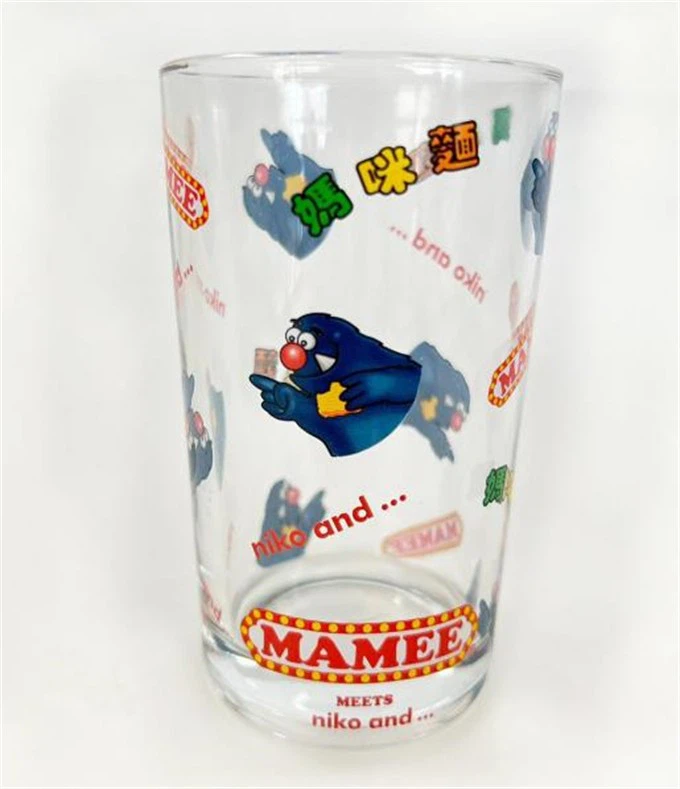

360 degree print on cups,bottles,tumblers,tapers,cylindrical objects |

|

Printable Length |

10mm-265mm(0.4''-10.5") |

|

Printable Diameter |

40mm-115mm(1.5''-4.5'') |

|

Printable Taper Angle |

0-7degree |

|

Print Resolution |

960×900 dpi or other resolution (optional) |

|

Printhead Quantity |

1-4pcs |

|

Print Configuration |

White+color(2heads) |

|

Print Speed |

Fast to 15 s/ pcs |

|

Ink Type |

Invironment-friendly UV Ink |

|

Curing Type |

UV light instant curing(Water cooling lamp) |

|

Power Requirement |

50/60Hz AC220/110±>10A |

|

Environment Temperature |

20℃ - 30℃ |

|

Environment Humidity |

40% - 65% |

|

Environment Cleanliness |

Similar to office environment |

|

Dimensions(L×W×H) |

1812×660×1820mm |

|

Weight |

300kg |

In order to ensure the print effect,before mass production,we often check firstly the samples,if they OK enough to meet we expect,we can go to do the mass production,so there,you may need to make sure all the colors and detail to be good,we can see the color profiles,if they are not good,we can use the calibration function to optimize again,generally,we do the color calibration when installing the print heads,simply install all the print heads can ensure we can print,but want to print perfect,calibration is necessary and critical.most of time,we will do the vertical calibration to make sure the all the heads align with each other,and then,all the every four channels need to overlap well with each other too when printing,then we will do the step calibration,that means, every step printing overlap with each step.after all of these calibration,your printing effect can be perfect.

FAQ

1. Is it easy to load and unload the product?

Yes,if you choose to load and unload the product by hand,it is still easy to operate,the operater can pick and put the product relatively randomly,and can ensure the printing process working well.

Hot Tags: inkjet printer for cylindrical objects, China inkjet printer for cylindrical objects manufacturers, suppliers, factory, Cylindrical Inkjet Printer, Digital Cylinder Printer, Cylindrical Screen Printer, Inkjet Printer for Cylindrical Objects, cylinder screen printing, helix digital cylinder printer

Previous

Cylinder Inkjet PrinterYou Might Also Like

Send Inquiry